Authors

-

Ngoc-Diem Duong

Laboratory of Biosensors; Department of Molecular and Environmental Biotechnology, Faculty of Biology and Biotechnology, University of Science, Ho Chi Minh City, Viet Nam; Laboratory of Molecular Biotechnology, University of Science, Ho Chi Minh City, Viet Nam; Vietnam National University, Ho Chi Minh City, Viet Nam; Pasteur Institute in Ho Chi Minh City, Viet Nam

-

Khai-Hoan Nguyen-Phuoc

Laboratory of Biosensors; Department of Molecular and Environmental Biotechnology, Faculty of Biology and Biotechnology, University of Science, Ho Chi Minh City, Viet Nam; Laboratory of Molecular Biotechnology, University of Science, Ho Chi Minh City, Viet Nam; Vietnam National University, Ho Chi Minh City, Viet Nam

-

Kim-Yen Thi Do

Pasteur Institute in Ho Chi Minh City, Viet Nam

-

Thuy-Dung Mai-Hoang

Laboratory of Biosensors; Department of Molecular and Environmental Biotechnology, Faculty of Biology and Biotechnology, University of Science, Ho Chi Minh City, Viet Nam; Laboratory of Molecular Biotechnology, University of Science, Ho Chi Minh City, Viet Nam; Vietnam National University, Ho Chi Minh City, Viet Nam

-

Nguyet-Thu Thi Nguyen

Pasteur Institute in Ho Chi Minh City, Viet Nam

-

Thuoc Linh Tran

Laboratory of Biosensors; Department of Molecular and Environmental Biotechnology, Faculty of Biology and Biotechnology, University of Science, Ho Chi Minh City, Viet Nam; Laboratory of Molecular Biotechnology, University of Science, Ho Chi Minh City, Viet Nam; Vietnam National University, Ho Chi Minh City, Viet Nam

-

Hieu Tran-Van

Laboratory of Biosensors; Department of Molecular and Environmental Biotechnology, Faculty of Biology and Biotechnology, University of Science, Ho Chi Minh City, Viet Nam; Laboratory of Molecular Biotechnology, University of Science, Ho Chi Minh City, Viet Nam; Vietnam National University, Ho Chi Minh City, Viet Nam

https://orcid.org/0000-0003-2782-5232

Keywords:

lateral flow immunoassay, nitrocellulose membrane, absorbent pad, conjugate pad, sample pad

Abstract

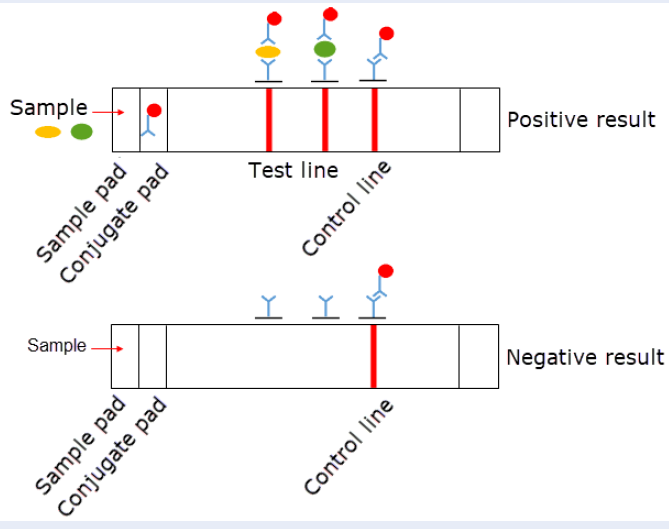

Background: Lateral flow immunoassay (LFIA) is a well-known method because of its extensive application in many fields, such as medical, food safety, and environmental analysis. LFIA is also under development for pathogen or protein detection, where rapid detection is essential. However, there are few studies on the optimal process for LFIA production.

Methods: This study aimed to evaluate the roles of the different materials that make up the LFIA strip, consisting of the sample pad, conjugate pad, nitrocellulose membrane, and absorbent pad. Different membranes and pads were evaluate regarding membrane permeability, generation of the test line, capillary flow time, and result visibility.

Results: The results indicated that the optimized LFIA strip is composed of four membranes and pads, including the CF3 sample pad, FF170HP nitrocellulose membrane immobilized with 1 mg of antibody, Standard 17 conjugate pad, and CF6 absorbent pad. The result was visually detectable within 15 minutes.

Conclusion: This optimization protocol could be a reference for the development of new test strips.

License

Copyright The Author(s) 2017. This article is published with open access by BioMedPress. This article is distributed under the terms of the Creative Commons Attribution License (CC-BY 4.0) which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.